Agile Parts Manufacturing

AND Production

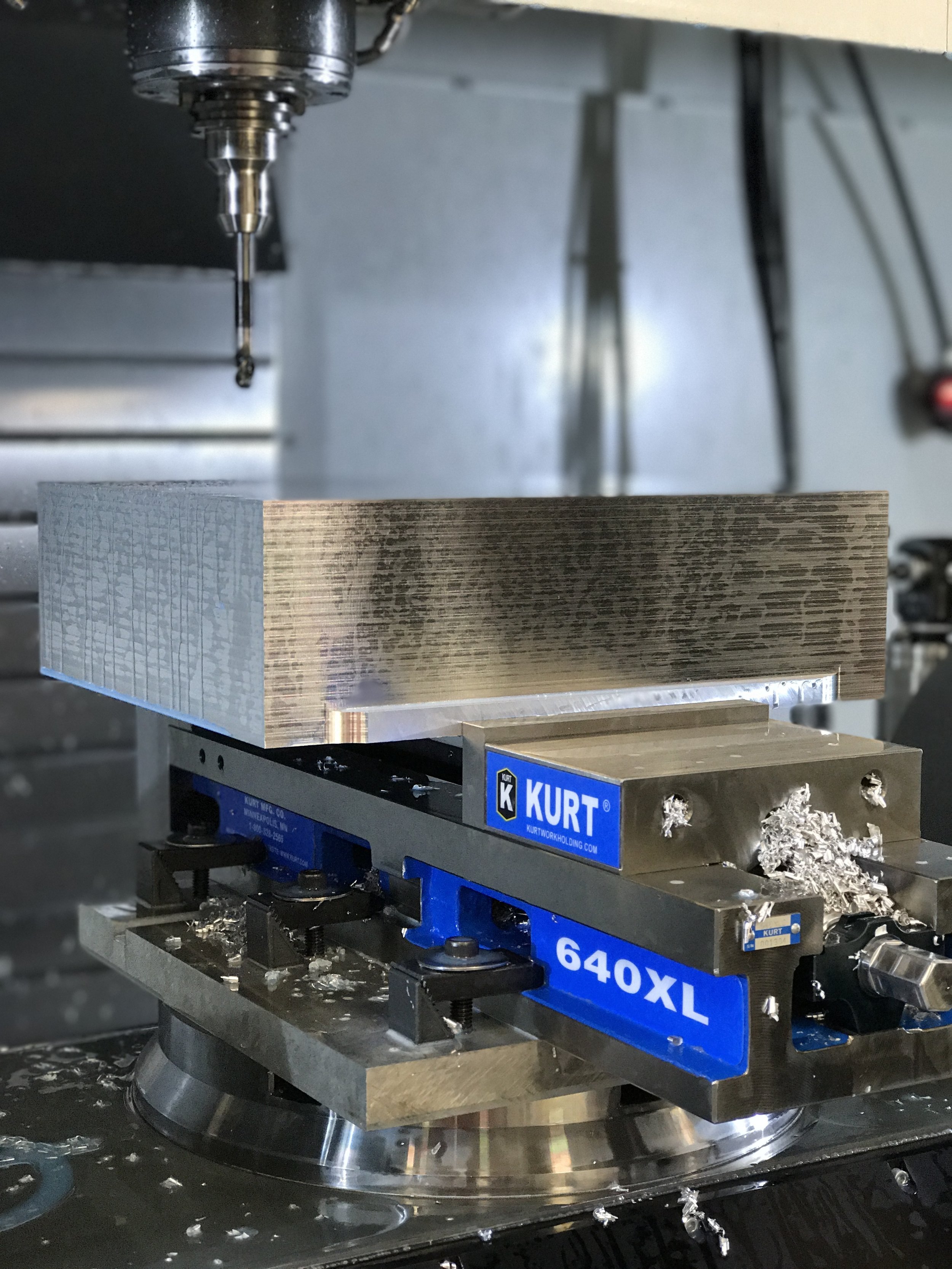

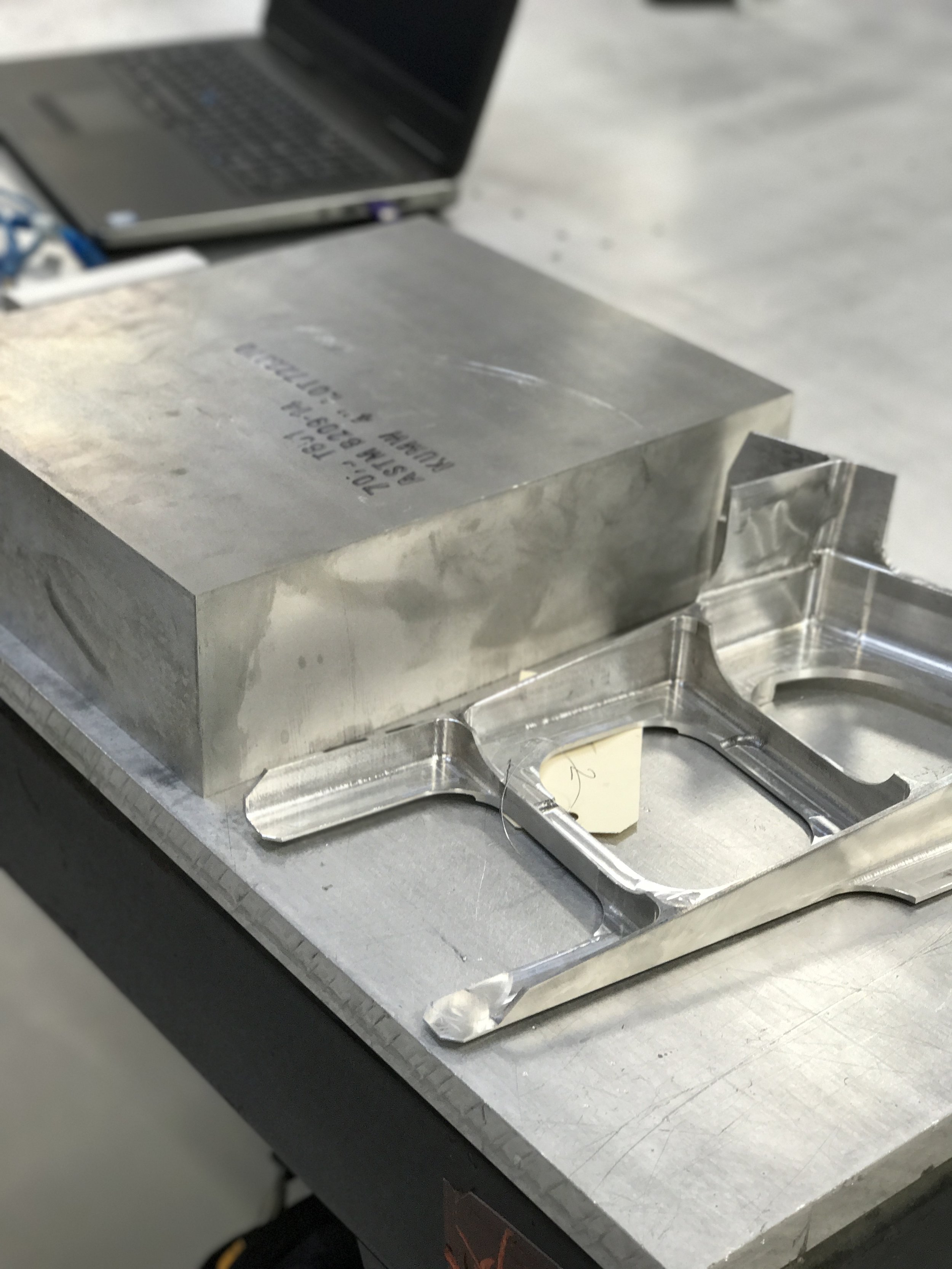

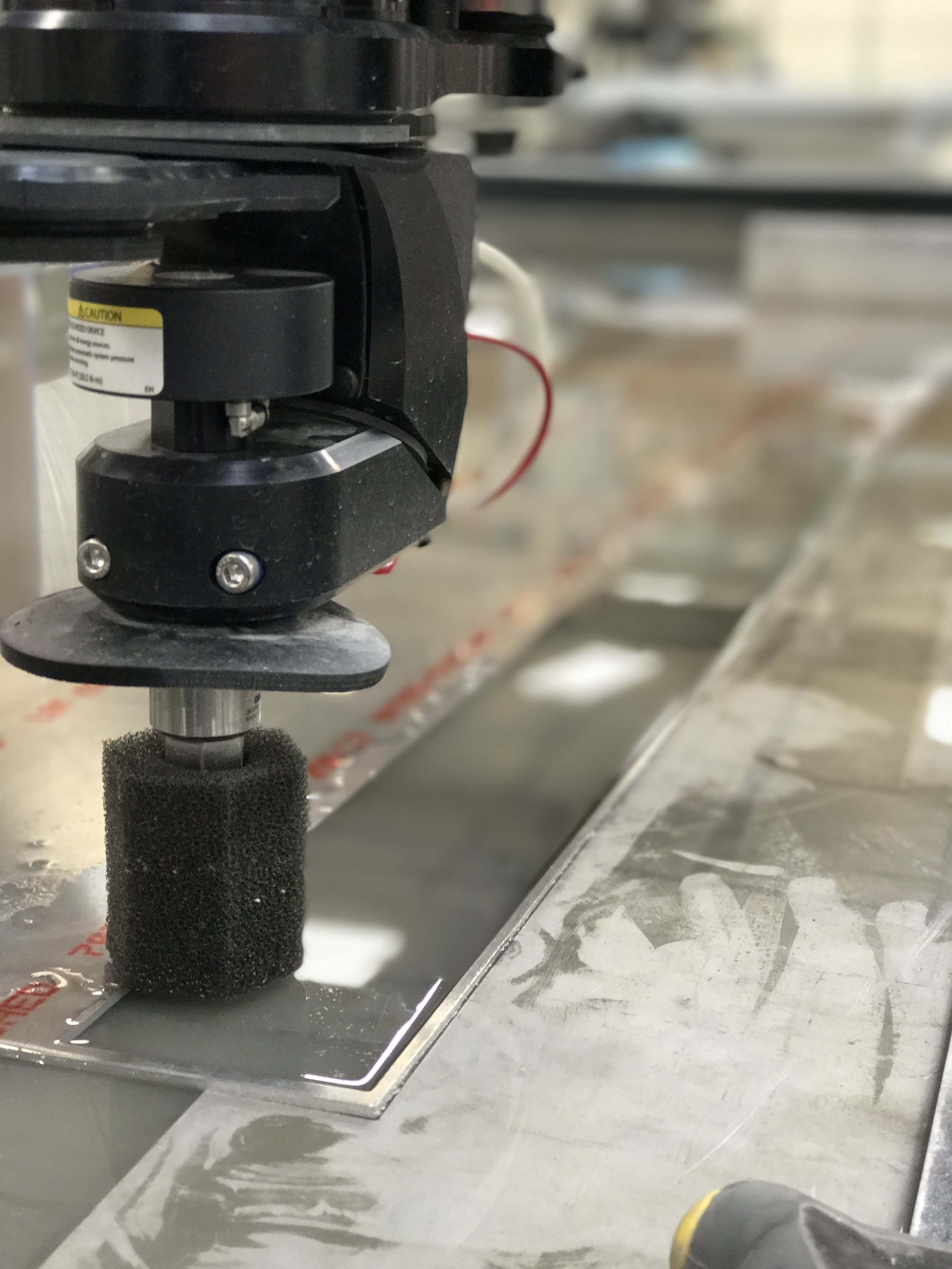

Platform Aerospace has integrated an agile R&D, engineering, design, and manufacturing facility, including over 43,000 sq. ft. of dedicated parts fabrication and production capacity. Our facility features leading-edge, fabrication, shaping, and cutting systems, producing aerospace quality carbon fiber composites, aluminum, steel, titanium parts and integrated component assemblies. Our parts fabrication provides for re-engineering and manufacture of aviation standard components utilizing the latest cutting edge fabrication equipment including, (4) 3/5-Axis CNC Machining Centers with capacities as large as 84” x 40”, Live Tool CNC Lathe, Tilting Axis CNC Waterjet, Precision Cut Saws, Large Cross Draft Paint Booth, electrical cable harness building equipment, carbon fiber part kits, and an extensive assortment of precision tools to get the job done right. With two Large Format 5-Axis Haas UMC-1000’s, Haas VF-9, Haas VF-2SS, and a Haas ST-30Y, all in-house, we have the capabilities and engineering knowledge to get aircraft needs done on-time and on-budget.

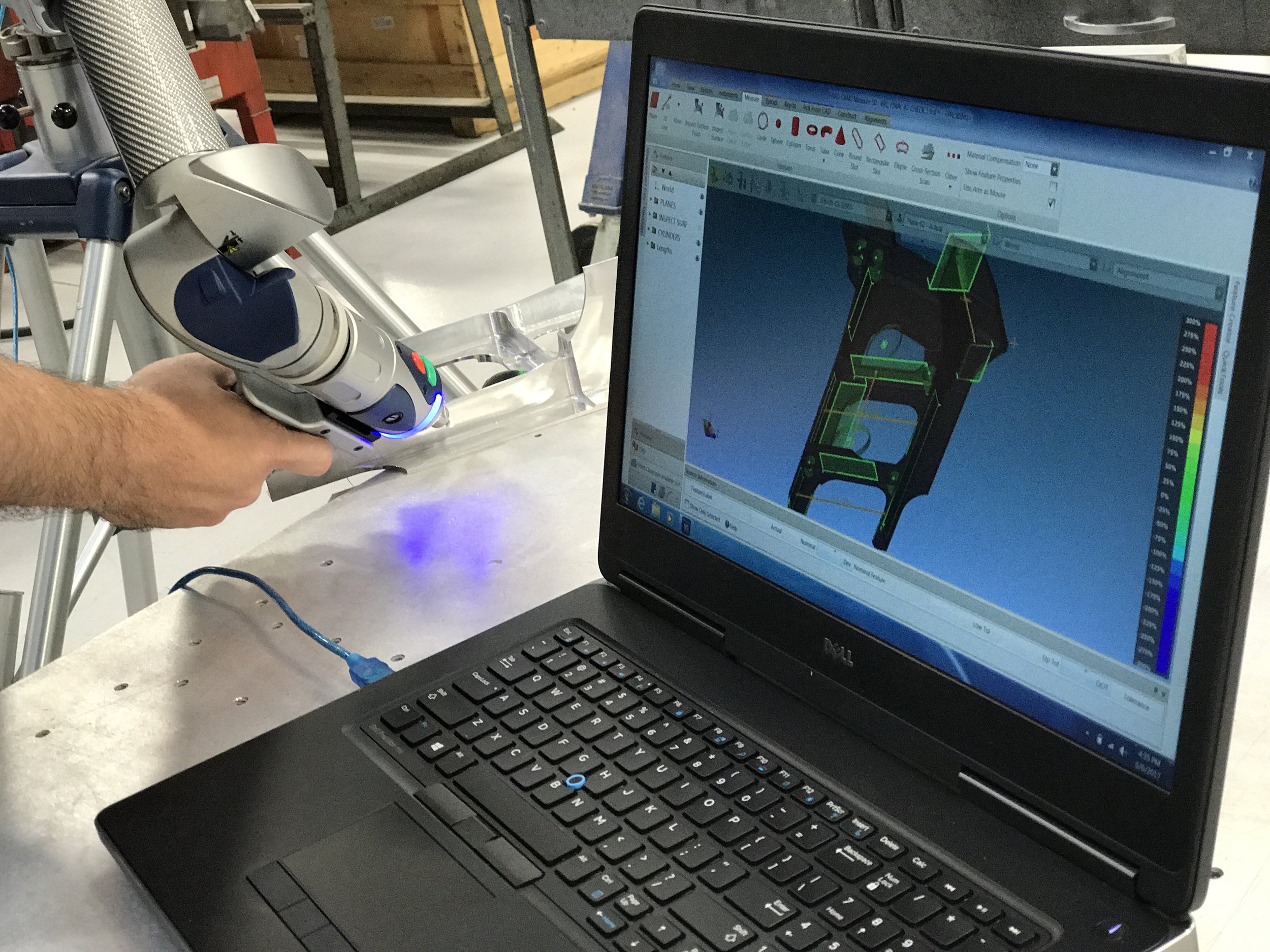

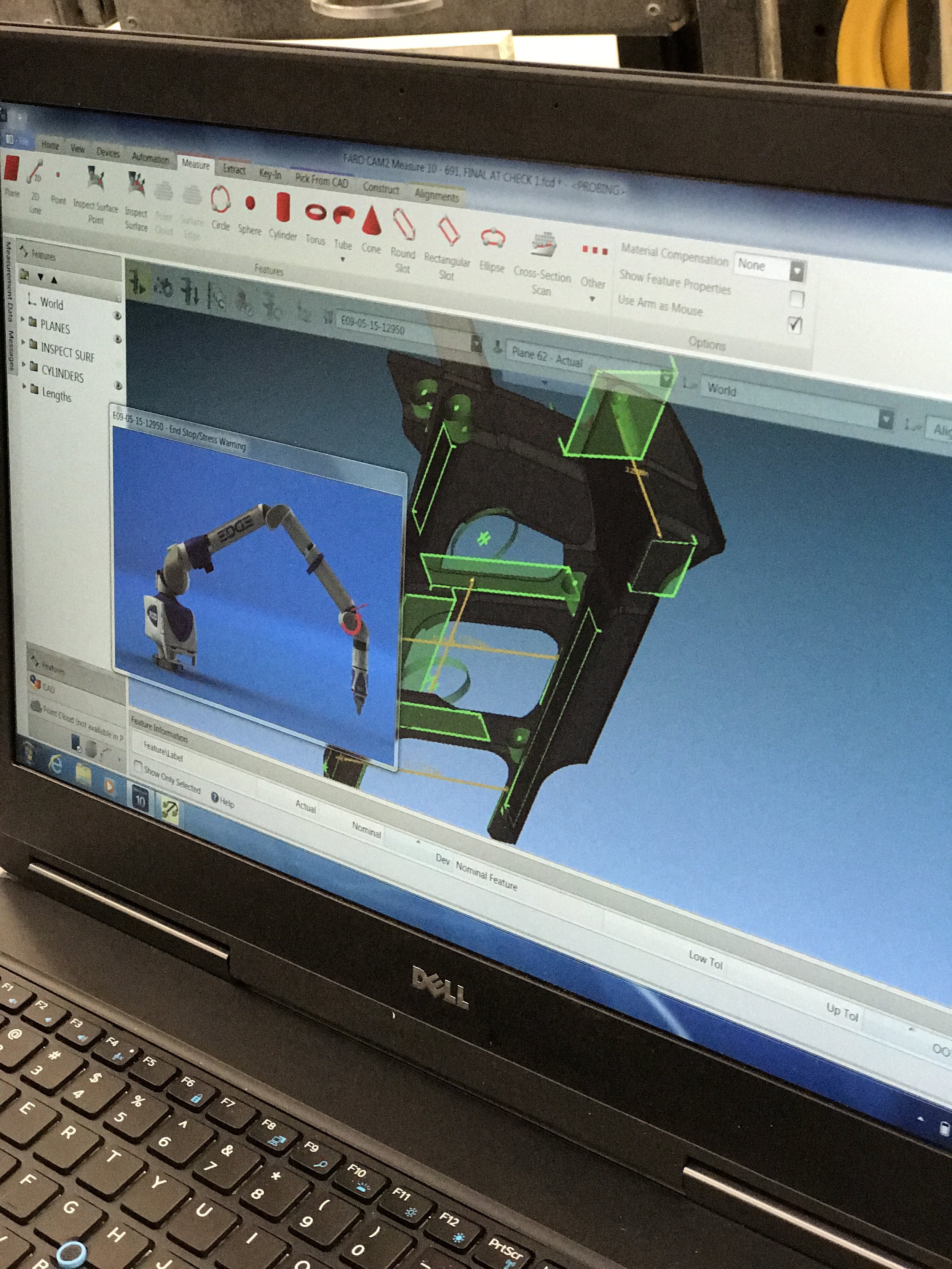

Our parts fabrication, production and finish quality processes and standards are certified by the Intertek AS9100D / ISO9001-2015 Quality Management System Authority and, meet and exceed all NAVAIR, FAA and Flight Operability protocol and standards. Pre and Post-engineering Quality Assurance and specification validation is measured with a Faro Arm to ensure precise tolerances are continuously met. Our team of certified aviation engineers and technicians ensure conformance of all material and components by utilizing 100% certified aviation-standard material and suppliers. Our staff and aerospace fabrication systems cut, shape, hone and extrude components from 8-inch diameter aluminum, steel, and titanium blocks, to stringent and certified aerospace standards and tolerances. Platform’s certified systems, staff and approach ensures all fabricated parts and products are delivered on time and in budget.

EQUIPMENT:

Haas UMC-1000 Large Format 5-Axis (Qty 2)

Haas VF-9 Multi-Axis CNC Machine

Haas VF-2ss

Hass ST-30Y

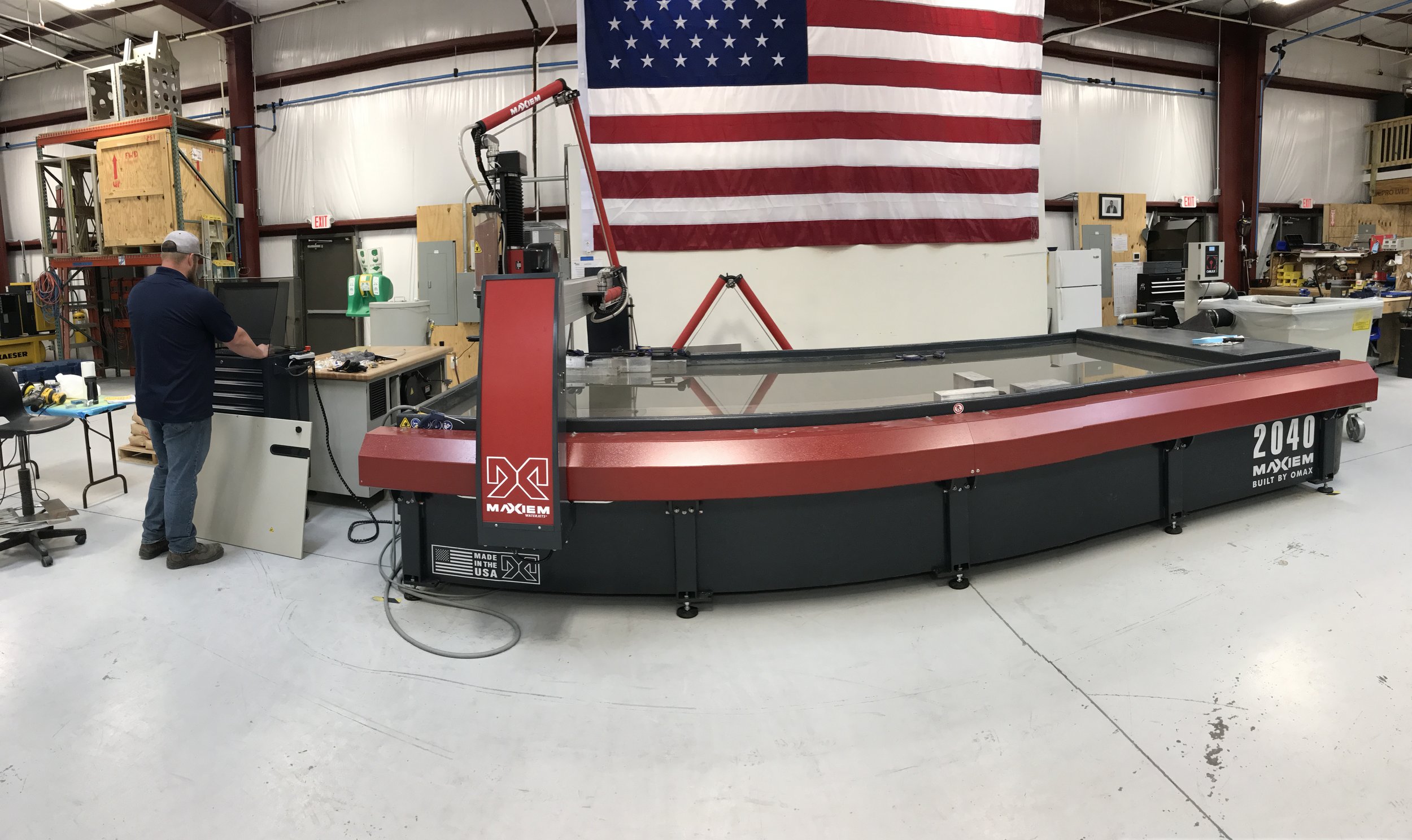

Omax Water Jet (2040 Maxiem)

HP Jet Fusion 580 Color 3D Large Production Printer

Faro Arm

MATERIALS:

Carbon Fiber Composites

Aluminum

Steel

Titanium

CAPABILITIES INCLUDE:

Carbon Fiber Layup

Carbon Fiber Repair

Honeycomb Repair

Radome Repair

Intercostal Rib

Composite Repair

Composite Manufacturing

CNC Press Brake

Metal Forming

Reverse Engineering

Intercostal Rib

Aircraft Structure

Structural Repair

Aircraft Structural Parts

Castings