UAV/UAS Capabilities

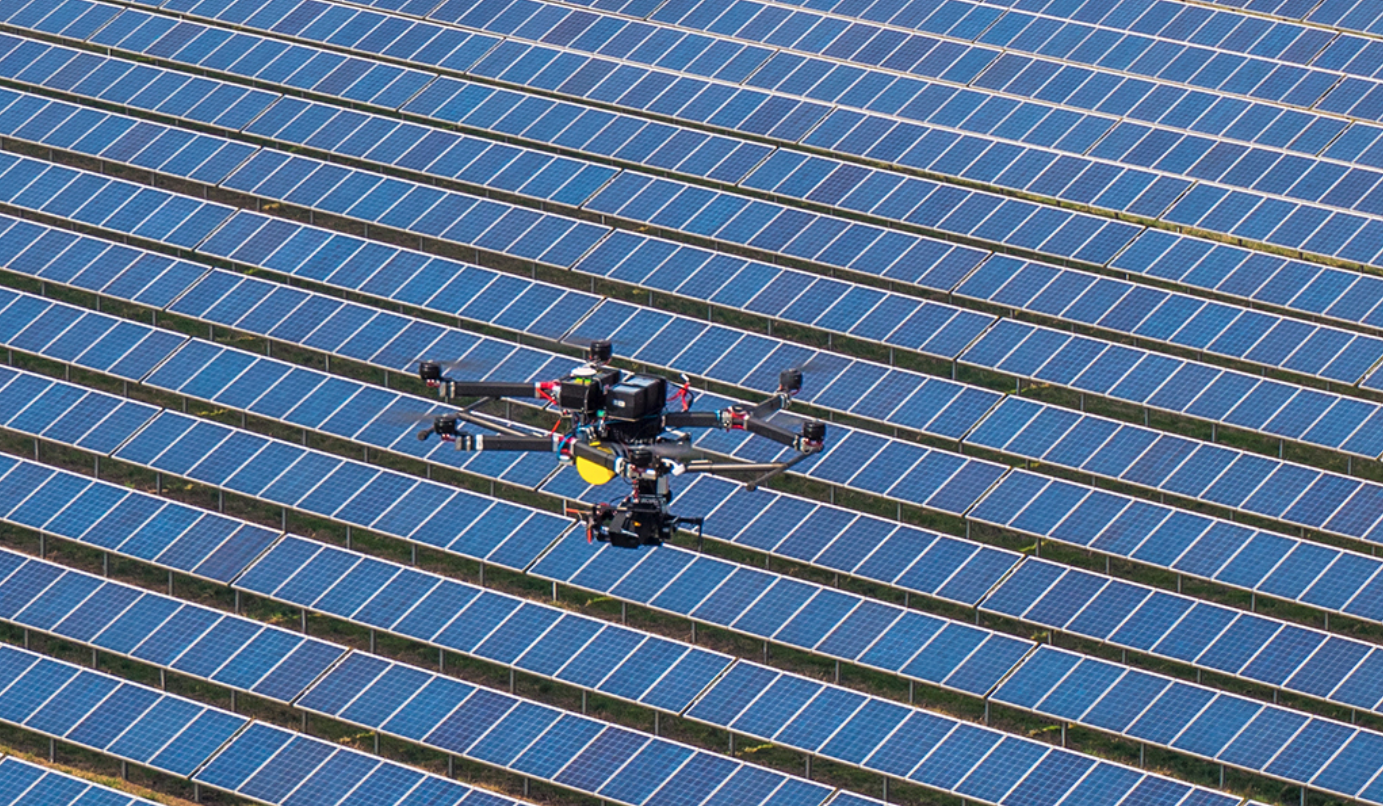

Platform maintains over 43,000 sq. ft. of aviation component and systems manufacturing space, capable of supporting various UAV, UAS and pilot-less drone design, production and modification. We provide small UAV PART 107 Class 1 and 2 flight services for clients who need inspections or systems flow (up to 55 lbs. and under 400 feet in Class G Airspace). Our design and production capabilities and aerial platform support facilities, includes the following:

Design, development and production of light-weight aviation-rated, Carbon Fiber components, assemblies, mountings and structural parts.

5 Axis CNC machine and Water Jet for cutting, shaping, or bending components from 8-inch aviation-rated steel or aluminum, for UAV replacement and modification components.

Platform also owns and operates Vanilla Unmanned a World Record-setting ultra-long flight endurance Unmanned Air Vehicle ISR platform.

MODIFICATION & INTEGRATION for UAV/UAS

Tiger Shark

Scan Eagle

Quadcopter Medium Lift UAV

GRYPHON DYNAMICS

DJI

Experience Includes:

In-depth aircraft and payload testing, validating platform capacity and performance

Ability to consolidate and increase payload capacity, capability, and effectiveness through end to end systems engineering and design analysis, while maintaining weight, fuel, on-station time and performance factors

Developed and implemented Design and Analysis of UAV as part of vehicle Reliability, Maintainability, Serviceability, Quality Index and payload verification

UAV/UAS Operational Verification

Our staff is certified to operate, maintain, and verify Tiger Shark, Small Family/Scale UAVs and DJI UAVs and integrated sensors, flight controllers, transmission sets and developer sets.

Qualified UAS sensor operator for:

RF Link

Video communications

Satellite communications

EO/IR sensor operations

UAV/UAS Systems Engineering

Developed and maintain proprietary code for use in UAS Facial Recognition systems, providing high resolution / high definition facial feature capture and communication to ground forces.

Designed UAS capability for operation in Denied Environment Mode. This allows UAV/UAS independent operations over terrain where Global Positioning Services (GPS), Instrument Navigation Systems (INS) and communication signals are denied or unavailable to the aircraft, while in flight. This allows the UAV autonomous operations and performance of programmed mission functions uninterrupted, based on internal navigation and mission sensors.

CAPABILITIES INCLUDE:

MODIFICATIONS

Prime / Paint

5 Axis CNC Machining

Waterjet cutting

carbon fiber

EXPEDITED MAJOR AIRCRAFT STRUCTURAL REPAIRS

REMOTE SITE INSTALLATION TEAMS

PREFABRICATED INSTALLATION KITS

PARTS MANUFACTURING

Sensor Integration:

EO/IR Cameras

LIDAR

SATCOM

Direct Finding (DF) Systems

SYSTEM INTEGRATION:

TIGERSHARK

SCAN EAGLE

GRYPHON

DJI